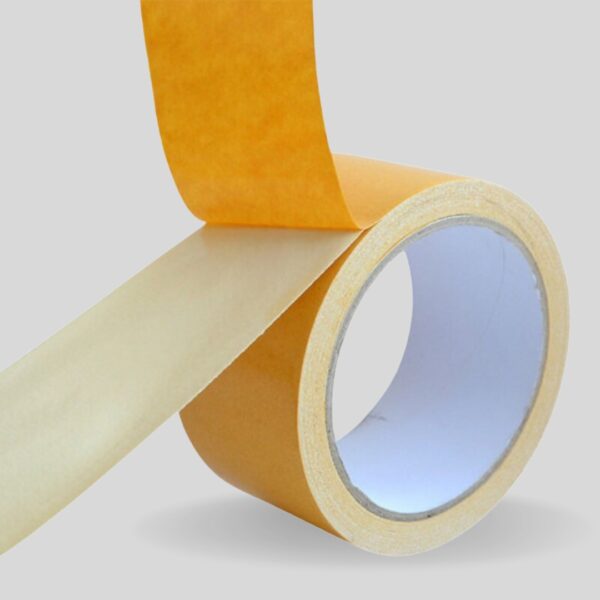

Cloth Plate Mounting Tape is a robust, double-sided adhesive tape made from cotton cloth, designed specifically for the flexographic printing industry. This tape features a strong natural rubber adhesive on both sides, coated for optimal adhesion and durability. Its specialized cushioning adhesive enhances performance in halftone and solid/block printing by providing excellent temperature and humidity resistance. Ideal for mounting printing plates onto sleeves and cylinders, it also finds use in carpet installation, offering easy handling with its paper release liners.